Natural stone working

The Mirt international company provides a full range of services as to work with natural stone - starting from material purchase abroad and design work up to manufacture and delivery of products to a facility and installation completion.

We can start cooperating as you bring us a finished project and we follow it to pick the necessary stone, or you can apply to us some project idea and we will refine it by joint efforts. We select decors and color schemes, choose the most optimal type of stone for your project.

Workflow

- Consultation

- Project sketch creation

- Selection of stone in Italy, Spain, Portugal depending on the stone chosen

- Issue of complete package of working drawings

- Issue of technical design specifications for construction operations and acceptance of premises before installation (a kind of technical inspection)

- Products manufacture

- Logistics and installation

You can invite our representative to a meeting with a client, so that during the meeting the client would promptly get answers to all questions and, moreover, you can have meetings with your client in the offices of our representative offices, which are already equipped with sets of stone samples.

Export and logistics process is important. Given our experience in the overseas market, we already clearly understand the laws of the countries in which we operate and this allows us to optimize the delivery process for our products.

Implementation of projects abroad

It is important to note that the implementation of projects abroad is not really an easy process, but due to the fact that we have representative offices in other countries with professional management team, we are able to maintain a project at all stages.

The project department in Ukraine works closely with managers abroad and, thanks to this, it is possible to promptly resolve any emerging issues.

Holistic approach

The great advantage of working with us is that the employees of different areas of focus work together finding solutions on adjacent structural units.

For example, there are often questions about joining marbles, parquetry and doors at sites where different contractors work. We have this issue solved at the projecting stage, not at the time of installation on a construction site. This helps to avoid many problems.

Technological processes

Details for single-tone floor coverings and walls are being made according to the designer’s drawing specifying sizes of details, texture direction and details location on marble slabs.

Pattern cutting is being made using sawing machine with diamond disk. Cutting mode is individual for different types of stone.

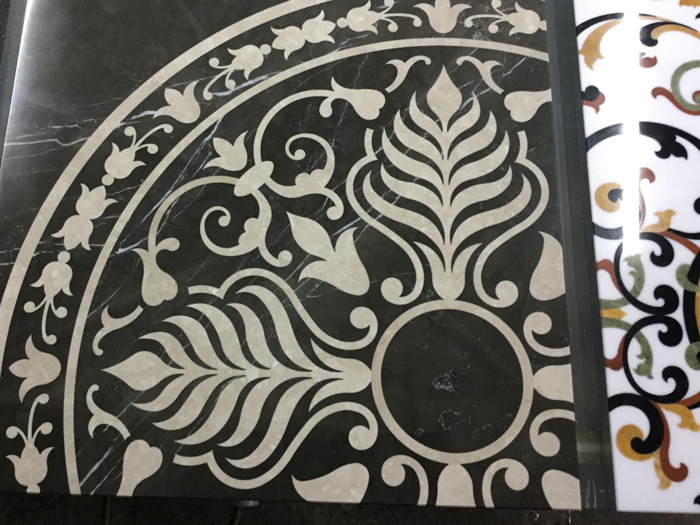

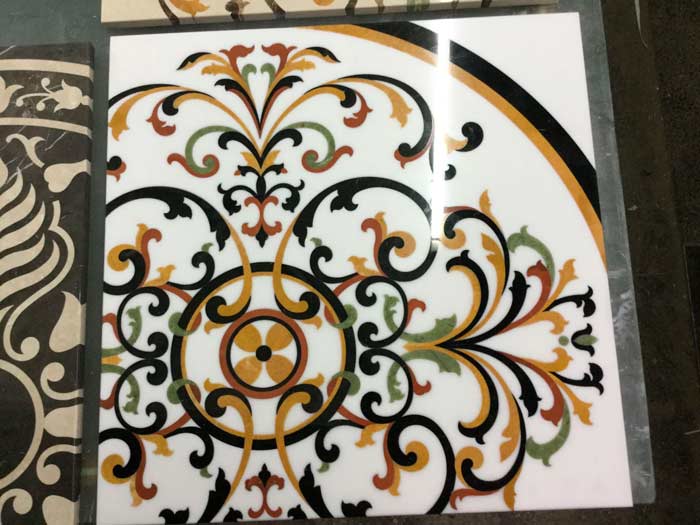

Inlay

The technology of marble inlays manufacturing is not very different from intarsia production in wood. Only materials and machines differ. To begin with, a drawing project with desired colors is being created. Next, a designer creates programs with details layout on marble slabs, by which the hydro-abrasive machine WaterJet cuts fragments of a panel picture.

Assembly into a panel picture or module is being done in a dry room manually by specialists in this type of work. After assembly, the panel picture or module must be re-polished. If the panel is part of the marble floor, the polishing takes place after finishing of laying, as the final stage.

Decorative stone carving

The main part of the work of decorative stone carving creation is being carried out with CNC machines. Approved decor is being built into a 3D model and control programs for the machine are being created with the help of a special program. The stone work-piece is being milled using a tool with diamond coating in two stages - rough and finishing.

After machining, the product is being sent to a sculptor for manual fine finishing and polishing as a final step.